'O' RINGS

To measure an O-ring, you will need a few basic tools such as a ruler or caliper. Here’s a step-by-step guide on how to measure an O-ring:

Select the appropriate measuring tool: You can use either a ruler or a digital caliper to measure the O-ring. A caliper provides more accurate measurements.

Determine the size you need: O-rings come in various standard sizes, so you need to know the specific size.

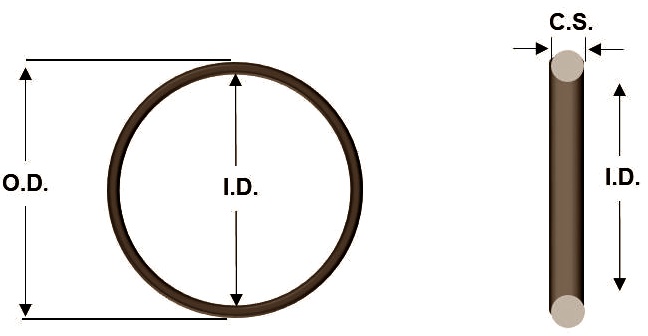

Measure the outer diameter (OD): Place the O-ring on a flat surface and measure the outer diameter across the widest point of the ring. If you’re using a ruler, align one edge with the widest point and read.

Measure the inner diameter (ID): Similarly, measure the inner diameter of the O-ring by placing the measuring tool across the narrowest point of the ring. If you’re using a ruler, align one edge with the narrowest point and read the measurement where the opposite edge ends.

Determine the cross-section diameter (CS): The cross-section diameter refers to the thickness or height of the O-ring. If you’re using a ruler, place the O-ring on its side and measure the height from the flat surface to the highest point of the ring.

Confirm the measurements: After obtaining the measurements for the outer diameter (OD), inner diameter (ID), and cross-section diameter (CS), double-check the values to ensure accuracy. Make note of the measurements or write them down for future reference.

We supply the complete range of BS standard sizes. We also manufacture non standard sizes This standard specifies the dimensions, tolerances, and materials for O-rings used in various industrial applications.

Materials

We manufacture different variety of rubber materials, including Perfluoro Elastomer (FFKM), AG Fluoropolymers (TFE, FEPM), fluoroelastomer (FKM), High Nitrile rubber (NBR), silicone rubber (FVMQ), Hydrogenated Acrylonitrile Butadiene Rubber (HNBR), Ethylene Propylene Rubber (EPR), Polyurethane (PU) and Ethylene Propylene Diene Rubber (EPDM), among others. The standard defines the dimensions of O-rings based on their inner diameter (ID), outer diameter (OD), and cross-sectional diameter (CS). It also includes tolerances for these dimensions to ensure proper sealing and fit.

Technical

Temperature : -10 ° C / + 300 ° C (Depending on material)

Size : 1.5 mm to 600 mm diameter.